Mechanical processing

FAR’s mechanical processing is carried out by a department specialised in meeting the needs of every client.

Thanks to the many years of experience in the world of aluminium die casting, FAR has gained excellent knowledge of mechanical processing, investing continuously in technologies and machinery to guarantee high quality levels.

Mechanical processing

FAR’s mechanical processing is carried out by a department specialised in meeting the needs of every client.

Thanks to the many years of experience in the world of aluminium die casting, FAR has gained excellent knowledge of mechanical processing, investing continuously in technologies and machinery to guarantee high quality levels.

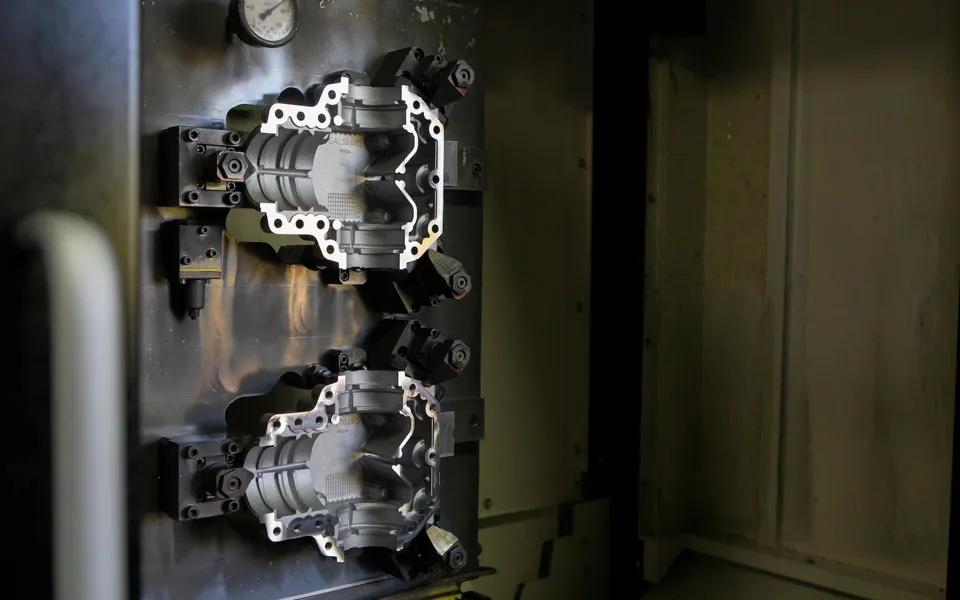

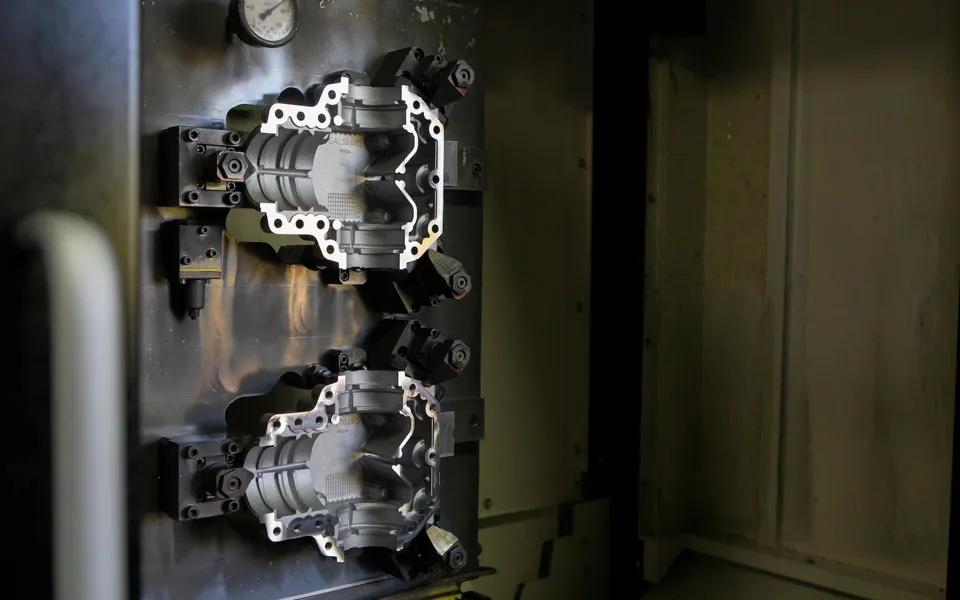

MECHANICAL PROCESSING DEPARTMENT

The Mechanical Processing Department is located just a few kilometres from the company’s headquarters: a 2,000 square metre plant in Vergato (Bologna).

An ad hoc Quality Department has been set up at the plant to control all the processes and guarantee the quality of the finished products.

The Mechanical Processing Department is equipped with:

- 2 horizontal 4-axle machining centres

(ENSHU GE 480 H and ENSHU GE 460 H) - 2 vertical 3-axle machining centres

(OKUMA MX and QUASER MK603S) - 2 vertical machining centres

(N°2 BROTHER TC-S2A) - 4 Famar lathes with “chain” loading

(N°2 FAMAR ERGO 250, FAMAR PRONTO 5, FAMAR ERGO 230) - 1 lathe with robotic loading

(DMG-MORI NLX 2500-700) - 3 lathes with manual loading

(N°2 OKUMA LB15 and OKUMA LB300) - 1 drill press

(SERRAMAK) - 2 Zeiss measuring machines

(CONTURA and DURAMAX)